From HyperBIKES to SMART CITIES PROJECTS and everything in between where performance take a new level, with BIANCA ADVANCED INNOVATIONS every challenge starts with the same question. How can we do it better?

WHAT WE DO

Solutions looking for needs.

Every solution looks for a problem. From biomedical to industrial design we approach everything as in the racing world where we are used to go beyond the limit. Needs are the starting point that unleash creativity and ideas.

STARTING FROM NEEDS

- What is your need

- What is your problem

- How is it usually solved

- Are we really sure?

Transformative Innovation

Transformative innovation involves creating something entirely new. This requires a high degree of creativity and risk-taking in contrast to incremental innovation, which focuses on improving existing products or processes.

Disruptive process

- Analyze the state of the art

- Destroy the path of linear development

- Develop creative paths out of the box

- Don't stop in front of impossible challenges

innovative solutions

Every problem requires different points of view, as in motorsport and competitions "performance" means looking for the limit without shortcuts. Innovative materials and processes allow the development of different and unusual solutions..

Open engineering development management

- in-house 3D scanning and modeling, reverse engineering and parametric design

- Advanced computational analysis in partnership with CompMech Pavia University

- Development of advanced materials and innovative processes

technologies to verify and test

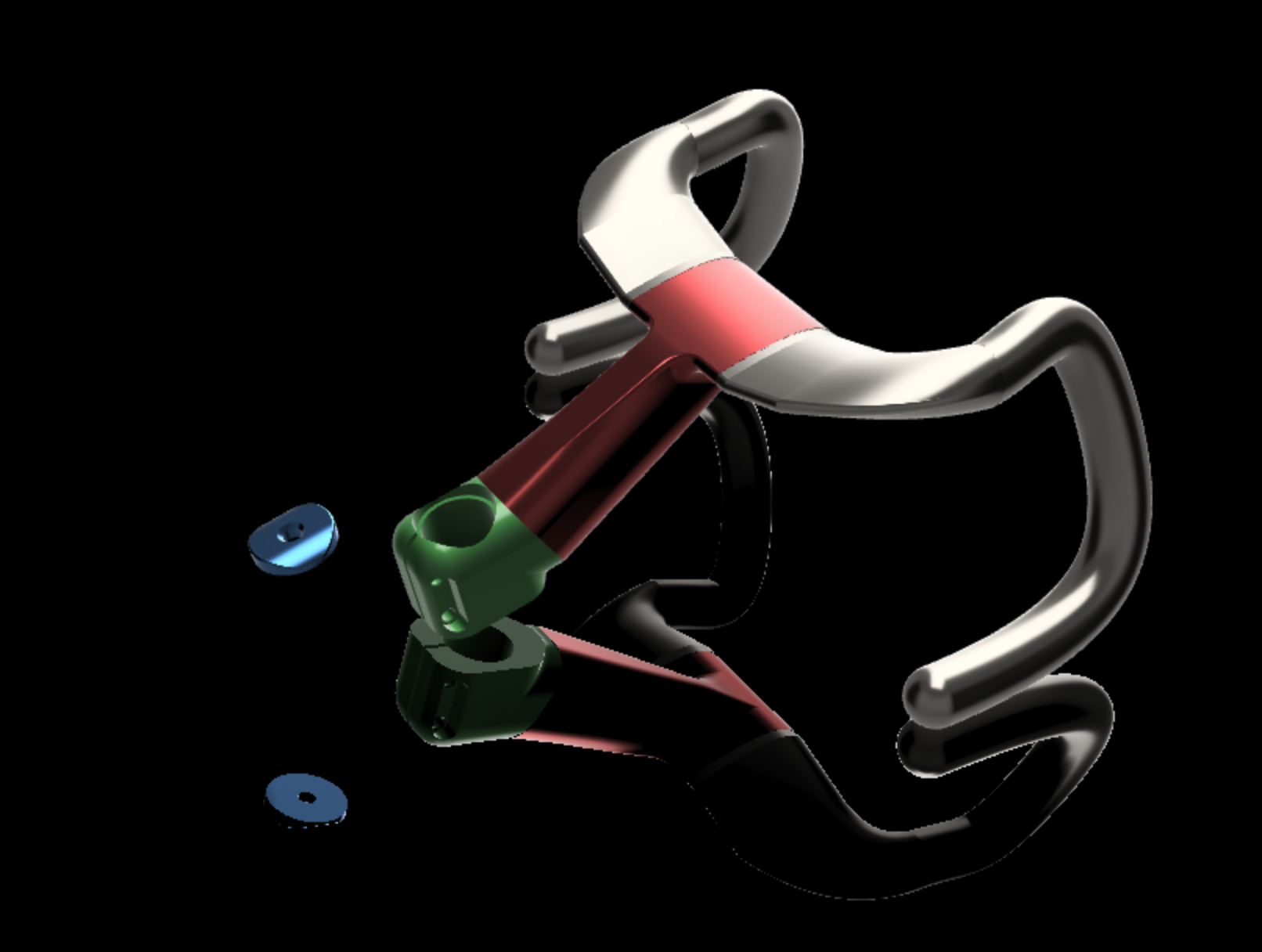

3D printing technologies have revolutionized the design and development process for high-performance products like the TOOT RACING track bike, enabling designers and engineers to create products that are optimized for performance and tailored to specific requirements.

Available technologies

- Fused Deposition Modeling (FDM)

- Multi Jet Fusion (MJF)

- Metal Electron Beam Melting (EBM)

- Metal Selective Laser Melting (SLM)

not only simulations

Data analysis by telemetry in real situations and simulation using computational fluid dynamics (CFD) and finite element analysis (FEA) is incredibly valuable for the development of high-performance products.

FROM DESKTOP TO reality

- FEA mechanical computational analysis

- CFD aerodynamic simulations

- Fatigue stress tests

- Telemetric sensors, accelerometers, inclinometers, pitot tubes

custom is the new standard

Bianca Advanced Technologies process allows you to define the ideal requirements so that the optimal solution is provided every time in concrete and repeatable objects in which customization becomes a standard.

why replicate?

- Composite reinforced pre-series

- Additive MJF plastic components

- Metal SLM or MJF custom production/series

- Handmade craftmanship and finishing

Performance as a passion

PERFORMANCE

The goal of optimizing performance is to create a product that meets or exceeds the needs and expectations of its users, whether that means achieving faster lap times on the track, delivering a better user experience for consumers, or improving efficiency and reliability for industrial applications.

New concept / IDEAS

New concept / design

New concept / engineering

New concept / delivery

SUSTAINABILITY

Sustainability with additive technologies involves designing and manufacturing products in a way that minimizes their environmental impact and maximizes their lifecycle efficiency. We use the most pionieristic advanced technologies but we are not driven by technologies. There is emotion in every aspect of our designs: creativity, intuition, inspiring better futures vision, genuine passion.

OPTIMIZATION

Design optimization: Additive technologies can be used to optimize the design of a product for sustainability, such as reducing weight, improving efficiency, and minimizing the use of non-renewable resources.

Futures

The balance between creativity and technology creates new and improved ways of living, working and playing. This can include everything from wearable technology to smart homes and cities that automate and optimize our daily routines. The same tools, techniques and methods used in developing racing components are applied to engineering challenges across land, sea and air at breakneck pace.

CHALLENGES

Our challenge addiction is fueled by a passion for innovation and pushing the limits of what is possible. Whether it is in the field of racing or in design and development, we are driven by a desire to constantly improve and find new solutions to complex problems.

DISRUPTIVE

ADVANCED INNOVATION

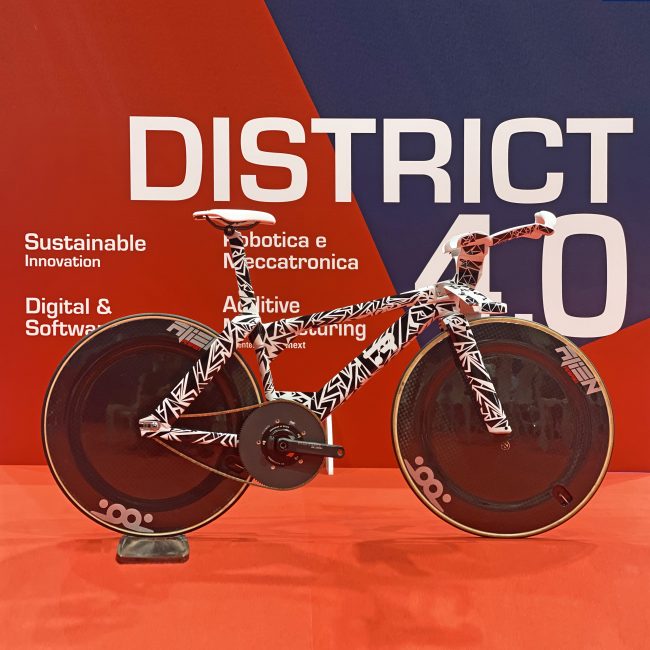

Transformative innovation involves creating something entirely new, in contrast to incremental innovation, which focuses on improving existing products or processes. "For Bianca Advanced Innovations, building the future is a transformative process. It is not a matter of putting rockets on a man to make him fly, but of transforming him into a butterfly, into an eagle. In the cycling performance sector, TOOT RACING goes beyond the evolution of the product, the frame, the components. The development of the process, from the idea to the study of materials, to engineering, to production is aimed at optimizing what the man can give. The best way to enhance the performance of an engine is to give it the best chassis it can have".

A.D.A.P.T.

Adaptive Design Advanced Process Technologies

A.D.A.P.T. is an advanced design protocol developed by TOOT Engineering, integrating biomechanical modeling, CFD-based aerodynamic simulation, physiological data, and high-performance materials for the structural and functional optimization of racing bicycles and components. At the core of A.D.A.P.T. is a rider-centered, data-driven methodology: the design process does not begin with a predefined geometry, but with the athlete’s optimal functional position, defined by movement, discipline, and competition environment. This position is simulated and validated through numerical models and experimental platforms (wind tunnel, track testing, ADWS-ORAI systems) to define the athlete’s best performance comfort zone. A.D.A.P.T. enables the development of high-performance systems that go beyond catalog geometries, offering maximum mechanical and aerodynamic efficiency compatible with the athlete’s physiological sustainability. It is a scalable process, applicable both to Olympic-level competition and to individual solutions for elite amateur cyclists.

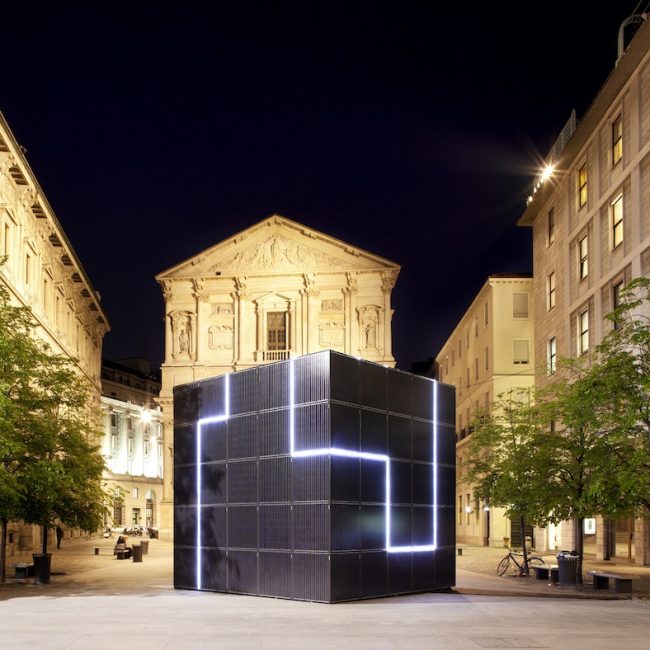

X23 PROTOTYPE TRACK BIKE PRESENTED IN WORLD PREMIERE

SPS ITALIA

Following the success of the THEFALCON project, the track bike made in SCALMALLOY® in additive manufacturing, designed by Romolo Stanco with the support of Bianca Advanced Innovations, TOOT RACING and T°RED BIKES, innovation in cycling does not stop. Project X2_ aims to bring 3D printing and transformative innovation to the Paris 2024 and Los Angeles 2028 Olympics. At the SPS fair in Parma, the X23 SWANIGAMI prototype will be presented in a world preview on the HP ITALIA stand. Thanks to the partnership with the 3DPROTOLAB and COMPMECH of the University of Pavia, themodel of the real 1:1 scale prototype was achieved, ready for UCI homologation and the realization in Scalmalloy together with APWORKS for the Participation in the 2023 World Championships in Glasgow UK. HP's Jet Fusion technology has made it possible to quickly and with great precision create and verify different solutions from a functional, technical and aerodynamics point of view, allowing for the choice of the best solutions and reducing project development times.

THE TEAM

WITH COMPMECH & 3DPROTOLAB @ PAVIA UNIVERSITY

The partnership started at the end of 2022 with the laboratories of the University of Pavia 3DPROTOLAB and COMPMECH has allowed the staff led by Romolo Stanco to develop new design paths both on the frame and the components and on the optimization of the athlete's position. The profound expertise of Prof. Gianluca Alaimo and Prof. Ferdinando Auricchio in the field of advanced materials and computational mechanics have made it possible to start a new path of "transformative innovation" codenamed X2_. BIANCA ADVANCED INNOVATIONS, 3D Protolab and Compmech UniPv bring their exceptional engineering, design, technology, simulation and manufacturing capabilities to develop innovative and disruptive solutions to any market sector with the same refinement used to make the fastest bikes in the world.

DREAMWORKS

Human intelligence shapes technology

Bianca Advanced Innovations takes a comprehensive and multidisciplinary approach to product development, leveraging expertise across multiple engineering disciplines to deliver cutting-edge solutions. At the heart of Bianca Advanced Innovations approach is a commitment to excellence in all phases of the product development process. Prototype work is an essential step in the product development process, allowing the team to quickly and efficiently test and refine different design concepts. Bianca Advanced Innovations has a dedicated prototyping lab, equipped with the latest 3D printing and additive manufacturing technologies, allowing the team to rapidly produce high-quality prototypes that accurately reflect the final product design. Additive manufacturing production is also a key component allowing the team to produce high-quality customized parts and components with exceptional accuracy and efficiency. This approach is particularly useful for producing complex, high-precision parts that may be difficult or impossible to produce using traditional manufacturing methods.